Laser Cutting for Artisans: How to Create Precise Designs with Ease

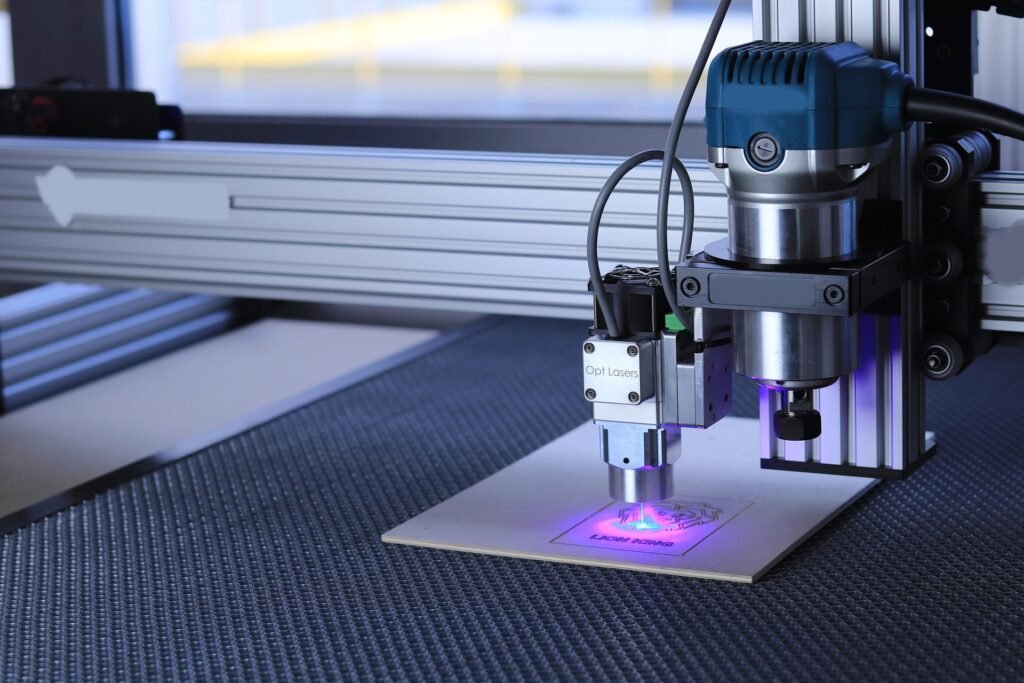

Laser cutting has revolutionized the work of artisans, providing a level of precision and ease that was previously difficult to achieve with traditional tools. With this technology, it is possible to create incredibly detailed pieces, ensuring uniform patterns and clean cuts in various materials such as wood, acrylic, and leather. This opens up a range of possibilities for customization and production on both small and large scales.

In addition to enabling a professional finish, laser cutting also offers speed and efficiency in project execution. Unlike manual cutting, which requires skill and time, this technology significantly reduces errors and material waste. With proper planning and the right software, it is possible to transform creative ideas into real products in a simplified manner.

Whether creating decorative pieces, souvenirs, or personalized items, laser cutting is an essential tool for any artisan looking to enhance the quality and efficiency of their work. However, to achieve the best results, it is crucial to understand the key aspects of this technology and how to use it correctly.

How Laser Cutting Works

The operation of laser cutting is based on the emission of a highly concentrated beam of light that heats and vaporizes the material, creating clean and precise cuts. The process is controlled by software, where the artisan can define the design and adjust cutting parameters such as power and speed.

There are different types of laser cutting machines, with CO2 lasers being the most common for artisans due to their versatility and cost-effectiveness. These machines can work with a variety of materials and offer high precision in details. For more elaborate designs, using vector design software such as CorelDRAW or Adobe Illustrator is essential.

Additionally, some advanced machines feature cooling and smoke extraction systems, ensuring a safer work environment and improving cut quality. Knowing your machine’s capabilities and limitations is fundamental to achieving impeccable results.

Main Materials Used

Artisans using laser cutting can work with various materials, depending on the type of machine and the desired effect. The most popular materials include:

- Wood: Ideal for decorative plaques, toys, and personalized pieces.

- Acrylic: Widely used for keychains, plaques, and modern decorations.

- Leather: Perfect for making wallets, bracelets, and accessory details.

- Paper and cardboard: Common in invitations, packaging, and layered crafts.

- Fabric: Can be used for precise cuts in sewing and garment customization.

Each material requires specific settings to ensure precise cuts and avoid damage. Therefore, testing before starting final production is always recommended.

Tips for Creating Precise Designs

To ensure your laser cutting projects achieve the highest quality possible, follow these tips:

- Choose good design software: Working with vector files allows for cleaner and more detailed cuts.

- Properly adjust machine parameters: Configuring the correct power and speed prevents imprecise cuts and material burns.

- Test before the final cut: A prototype helps correct errors before large-scale production.

- Keep the machine lens clean: This prevents power loss in the beam and ensures sharper cuts.

- Use quality materials: The choice of good material directly impacts the final product result.

- Organize cutting files properly: Separating different types of cuts (internal and external) prevents failures and material waste.

Step-by-Step Guide to Creating a Laser Cutting Project

If you want to create a precise design using laser cutting, follow this simple step-by-step guide:

- Define the design: Use software such as CorelDRAW or Illustrator to create or edit a vector design.

- Prepare the material: Choose and position the material correctly in the machine.

- Adjust the settings: Configure the laser’s power, speed, and focus according to the material.

- Run a test cut: Cut a small piece of material to check if the settings are correct.

- Execute the final cut: With the settings adjusted, start the definitive cut for your project.

- Finishing and cleaning: Remove excess residue and, if necessary, sand or varnish the piece for a better finish.

- Personalize your piece: If desired, add painting, laser engravings, or other details to make your project even more unique.

Laser cutting is an excellent tool for artisans looking to optimize production, ensure quality, and expand their creative possibilities. With knowledge and practice, it is possible to transform any idea into reality, gaining a competitive edge in the craft market. Additionally, investing in good training and high-quality materials can further elevate the level of your creations, enabling the development of a unique and attractive portfolio for clients and partners.